Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

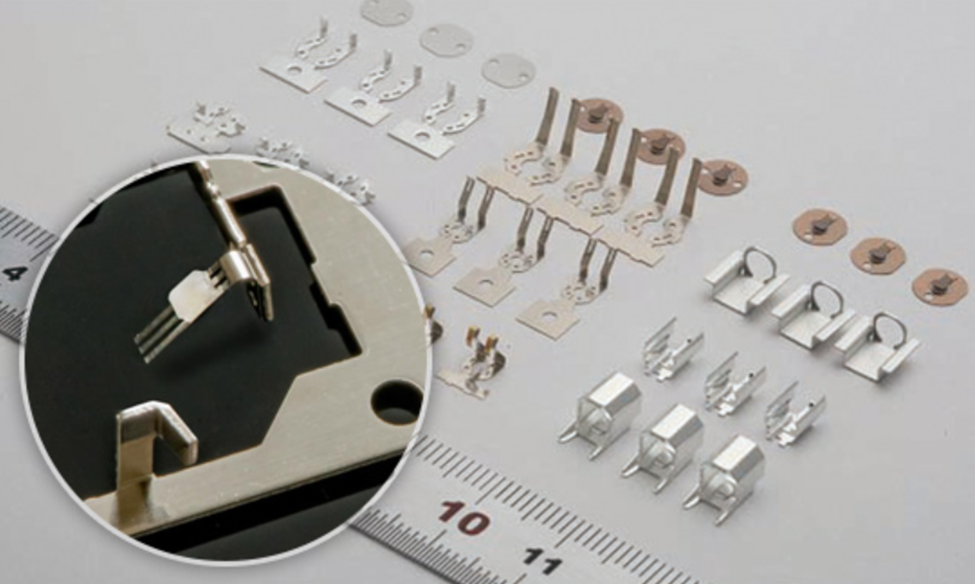

Precision stamping is a metal forming technique used to transform sheet metal into specific shapes through the application of localized compressive forces. It is commonly employed in the manufacturing of automotive components, metal parts, medical devices, consumer electronics enclosures, and countless other applications where precision is important. While metal stamping offers many benefits, achieving the desired level of precision can present unique challenges. Because of its sensitivity to variations, precision stamping often necessitates prototyping before full-scale production to validate the design and manufacturing approach.

Understanding Precision Stamping and Prototyping

As mentioned above, precision stamping refers to the manufacturing process of transforming sheet metal into intricately shaped components through the precise application of localized compression forces using precision dies or forming tools. It allows manufacturers to create metal parts with complex features, tight dimensional tolerances, and smooth surface finishes through a single stroke. When executed properly, precision metal stamping delivers unparalleled geometric accuracy and precision in metal forming.

Prototyping in the metal stamping industry refers to the process of fabricating initial exemplar parts based on design specifications before full-scale production. Its purpose is to help validate product design for functionality, manufacturability, and quality. Through metal stamping prototyping, engineers can simulate the actual stamping process to identify potential issues with part design, tooling, or the manufacturing approach before significant costs are incurred in tool fabrication and production setup.

The Importance of Prototyping in Precision Stamping

While precision stamping is highly effective for shaping complex metal components, achieving minute tolerances consistently throughout large-scale production presents unique demands. As such, the intersection between precision stamping and prototyping warrants a closer examination of how prototypes help validate designs and manufacturing approaches for optimal production results.

? Analyzing Precision Stamping Requirements

The complexity of precision-stamped parts usually demands intricate die designs which includes many small features, such as slim wall thicknesses, accurate hole placement, and delicate geometries. Even minuscule variations in die wear, material properties, lubrication, or forming pressures could lead to dimensional deviations or defects in critical areas.

While techniques like die tryout help optimize the process, validating the entire manufacturing approach through a sheet metal prototyping phase is necessary as it ensures predictable performance and superior part quality over long production runs.

? Benefits of Prototyping in Precision Stamping

While prototyping involves additional time and costs upfront compared to direct production, it provides several benefits for precision stamping processes. These include:

ü Error Identification: Prototypes help detect design issues, tooling errors, and process malfunctions early before full-scale manufacturing. This prevents expensive reworking.

ü Optimizing Tooling: Through prototyping, die modifications can be made incrementally to improve tool life, part formability, and dimensional stability of stampings.

ü Quality Assurance: Validating design and process via prototypes establishes production feasibility and helps achieve consistent quality from the start of full production.

ü Cost Reduction: Identifying and resolving problems at the prototyping stage minimizes scrap, rework, and downtime costs during production scale-up and long-term runs.

Factors Influencing the Decision to Prototype

Several key factors influence the decision to prototype precision-stamped components. These include the following:

? Project Complexity

Highly intricate parts with tight tolerances, narrow dimensional ranges, and complex geometries almost always require prototyping.

? Tolerance Requirements

Jobs specifying tight positional tolerances (e.g. +/-0.005 in) or smaller necessitate prototyping due to sensitivity to process variations.

? Risk Mitigation

Prototyping helps mitigate risks of unexpected design changes, tooling issues, dimension deviations, and defects during production.

? Time Constraints

With short timelines for volume production, prototyping allows for resolving design and process problems beforehand to avoid delays.

Hashimoto Precision Specializes in Custom Metal Stamping Services and Prototyping

At Hashimoto Precision, we specialize in revolutionizing metal stamping and prototyping to redefine the boundaries of precision engineering. With over two decades of relentless commitment to excellence, our cornerstone lies in crafting custom metal stamped components that set new standards for accuracy and quality.

? Pioneering Custom Metal Stamping

Our expertise extends beyond the conventional. We pride ourselves on pushing the limits of possibility in custom metal stamping. From automotive components to intricate medical devices and beyond, our capabilities encompass a diverse array of industries. Our in-house mastery spans the entire spectrum - from project ideation to the seamless execution of complex designs.

? Prototyping Excellence

Prototyping isn't just a phase for us; it's a strategic advantage. We understand the critical role it plays in validating designs and refining manufacturing approaches. By simulating the stamping process meticulously, we preemptively identify potential challenges, ensuring a flawless transition to full-scale production.

? Unparalleled Precision and Quality Assurance

ISO9001, ISO14001, and IATF16949 certifications underscore our unwavering commitment to quality. Our state-of-the-art machinery allows us to craft parts with unprecedented precision, even from metals as thin as 0.02mm. Each component undergoes rigorous scrutiny to guarantee adherence to the most exacting standards.

Conclusion

Precision stamping is an art that demands perfection. The harmony between precision stamping and prototyping is crucial for flawless results.

At Hashimoto Precision, we redefine excellence in custom metal stamping and prototyping. Our commitment spans two decades of pushing boundaries and ensuring unparalleled precision. We don’t just prototype; we strategize, foreseeing challenges before they arise. We stand ready to collaborate, utilizing our expertise and cutting-edge technologies to elevate your projects to new heights of precision and success. Let's create excellence together.

Also Read

1. 5 Reasons Why Precision Stamping is the Key to Manufacturing Success

2. The Importance of Precision and Accuracy in Medical Stamping

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox